85% Cost Saving

On MaintenanceThe Ultra Clean Method

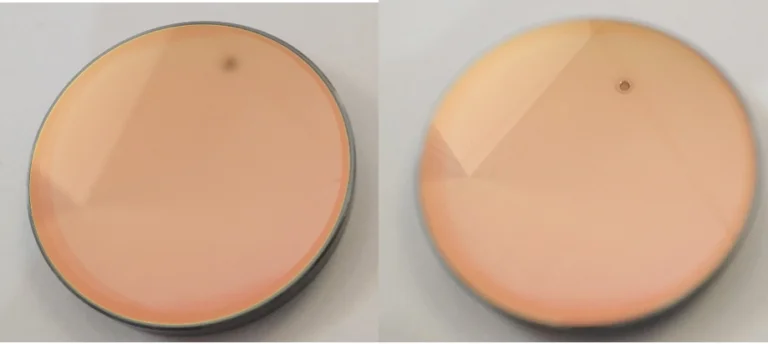

Our special refurbishment technique removes the contamination and extends the optics life and thus reducing the customer’s maintenance cost. Periodic ULTRA-Cleaning of Discharge tubes prevents further deterioration of mirrors and ensure the quality BEAM DELIVERY LIKE NEW as always.

- Reduces heart-aching maintenance costs from costly OEM optics.

- Used successfully by customers all around INDIA.

- Restores mirror properties to perform like new OEM standards.